Anti Moisture Powder is a plastic additive that absorbs moisture from the raw material. Plastic product including extrusion, injection and film process is made of plastic raw material melt with high temperature by extrusion moulding equipment. The quality of plastic product is directly and closely related to the compaction and drawback rate for moulding product. The moisture content in raw material will directly impact to the quality of plastic product. The moisture will become steam in the process of plastic product and lead to drawback with bubble, crackle, spot and hole in plastic product, so that it influences the mechanics property and appearance of plastic products.

In order to improve the quality of plastic product and wipe off the moisture & provide Shining & Strength in raw material, currently people mainly adopt heating and drying the raw material before process. This process needs manufacturer or buys additional drying equipment with high temperature. Which increase technology process, the production cost and labor.

Importance of Anti Moisture Powder :

- The end product is solid and does not have any porosity

- Improved surface finish of the plastic granules

- Increases production

- Reduces machine load

- Increases the strength of finished product

- Minimizes air block inside recycling die/ mold, Minimizes production wastage

- Controls production related problems in worn out screw & barrel to an extent

- Lowers production cost by Heat generation

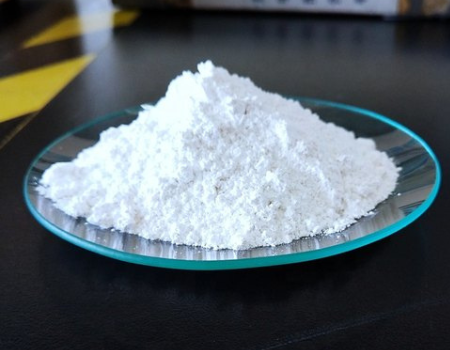

Technical Specifications of Anti Moisture Powder :

- Molecular Weight : 37.85

- Density : 0.70 g/mL

- Form : White Crystalline Solid

- Melting Point : Decomposes above 400 °C